The common faults of the five-axis repeater and their diagnosis and elimination methods are as follows:

An axis does not work and prompts to view the fault code:

Err-13: Overvoltage, which may be caused by insufficient power supply or continuous switching power supply. The solution is to increase the voltage or stop for more than 30 seconds before turning on

Err-14: Overcurrent, which may be a short circuit or ground of the motor cable, or a damaged driver. Lines and drives need to be checked

Err-16: Overvoltage, possibly because the motor cable is short circuited or grounded, or the motor is running with resistance. It is necessary to check whether the line and the machine are running beyond the limit

Err-21: encoder communication error, you need to check the encoder cable and plug to ensure correct connection

Automatic spraying and paint supply system Problems:

Check the air switch to ensure that all air lines are free of air leakage, blockage, and impurities, water, and oil. At the same time, check whether the suction tray, filter and spray gun of the pump are clean, free of dust and stolen goods, and clean

Mechanical failure:

Including abnormal vibration, heat and sound, may be caused by cracks in the structure of moving parts, clearance changes and other reasons

Fluid property failure:

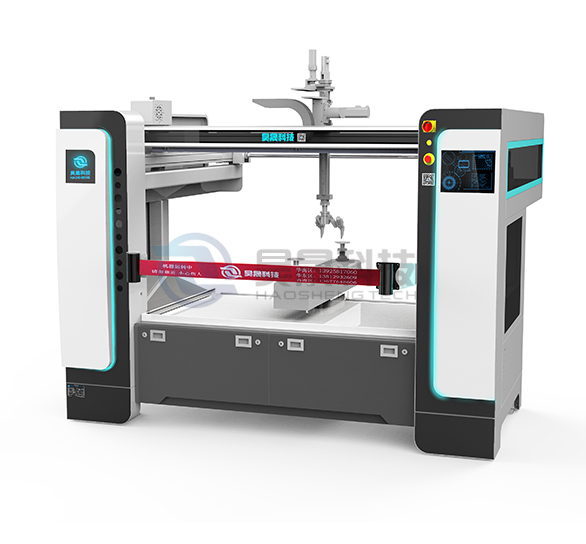

Five axis reloader

It is characterized by temperature difference, abnormal pressure, insufficient exhaust volume, which may be the failure of the suction filter, piston ring, air valve, cooling waterway and other parts

Mechanical function failure:

Typical mechanical failures include fracture of connecting rod bolts, piston rings, crankshaft, valve plates, cross, cylinder and cylinder cover, burning tile, motor failure, etc

Fault diagnosis method:

Including visual thermal performance parameter monitoring, vibration and noise monitoring, lubricating oil analysis, expert systems and networks

Oil monitoring:

It is divided into the analysis of the physical and chemical properties of the oil itself and the analysis of the wear information of the friction pair in the oil, including spectral analysis, ferrography analysis, particle counting and so on